Unleashing Peak Performance: Choosing the Best York YVAA Microchannel Replacement for Industrial Cooling Systems

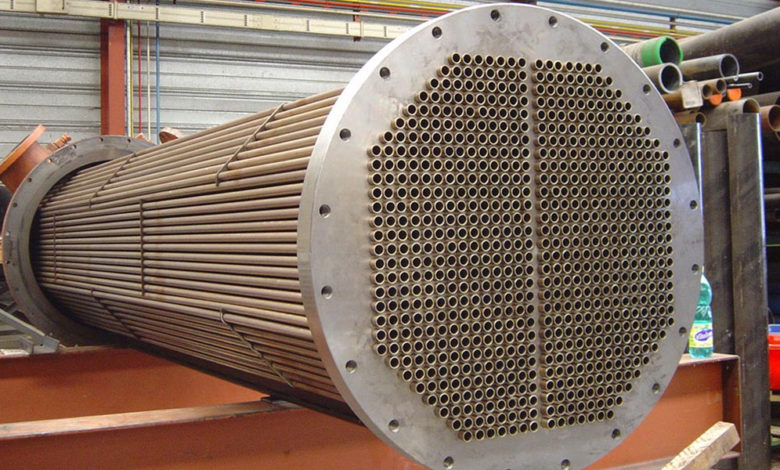

In the ever-evolving landscape of industrial equipment, the efficiency and reliability of cooling systems play a pivotal role in ensuring uninterrupted operations. York, a stalwart in the HVAC industry, continues to set benchmarks with innovative solutions tailored for the demands of industrial applications. At the heart of industrial cooling excellence lies the York YVAA microchannel – a crucial component that warrants careful consideration when replacement becomes necessary. This article aims to guide industrial professionals in selecting the best York YVAA microchannel replacement, highlighting key factors, benefits, and considerations for optimizing industrial cooling systems.

The Significance of York YVAA Microchannel Replacement

The York YVAA microchannel, a sophisticated component of industrial cooling systems, is subject to wear and aging due to continuous usage, environmental factors, and operational demands. When the efficiency of a cooling system starts to decline or issues such as leaks and corrosion arise, opting for the best York YVAA microchannel replacement becomes imperative. This strategic decision is essential for maintaining optimal performance, minimizing downtime, and ensuring the longevity of industrial processes.

Key Factors Driving the Need for Replacement

Efficiency Optimization:

The primary driver behind York YVAA microchannel replacement is the pursuit of optimized efficiency. Newer microchannels often incorporate design enhancements and technological innovations that contribute to superior heat dissipation, resulting in improved cooling performance and energy efficiency.

Adaptability to Changing Industrial Needs:

Industries are dynamic, with cooling requirements evolving over time. The best York YVAA microchannel replacement allows for the adaptation of cooling systems to changing industrial needs. Upgrading to newer microchannels ensures that the cooling capacity aligns with the current demands of industrial processes.

Extended Equipment Lifespan:

Regular maintenance, including timely York YVAA microchannel replacement, is key to extending the lifespan of industrial cooling equipment. Addressing wear and tear promptly helps industries avoid major issues and disruptions, maximizing the longevity of their cooling systems.

Environmental Considerations:

York, known for its commitment to sustainable HVAC solutions, often introduces eco-friendly advancements in its technologies. Opting for the best York YVAA microchannel replacement may present environmental benefits, such as reduced refrigerant usage or improved energy efficiency, aligning with the growing emphasis on sustainability in industrial practices.

Choosing the Best York YVAA Microchannel Replacement

Microchannel Type:

York offers a range of microchannel options, each designed for specific cooling needs. Assess the unique requirements of the industrial application and choose the microchannel type that aligns with those needs. The best replacement microchannel should seamlessly integrate with the existing cooling system.

Performance Enhancements:

Consider the performance enhancements offered by the replacement microchannel. Look for features such as improved heat dissipation efficiency, enhanced corrosion resistance, and advanced design elements that contribute to superior overall cooling system performance.

Environmental Impact:

Evaluate the environmental impact of the replacement microchannels. The best York YVAA microchannel replacement should align with sustainable practices, potentially offering benefits such as reduced carbon footprint or compliance with environmental regulations.

Compatibility Check:

Ensure that the replacement microchannels are compatible with the existing components of the cooling system. The best replacement microchannel seamlessly integrates with the rest of the equipment, minimizing the risk of operational issues and ensuring optimal system performance.

Budget Considerations:

Assess the budget and cost implications of York YVAA microchannel replacement. While the best replacement microchannels may have a higher upfront cost, the long-term benefits, including enhanced efficiency and reduced operational costs, often justify the initial investment.

Benefits of Opting for the Best York YVAA Microchannel Replacement

Superior Heat Dissipation Efficiency:

The best York YVAA microchannel replacement is designed to offer superior heat dissipation efficiency, ensuring more effective cooling processes and allowing industrial equipment to operate within optimal temperature ranges.

Space Optimization:

Replacement microchannels, especially the best options from York, contribute to space optimization in industrial settings. Their compact design allows industries to make efficient use of available space without compromising on cooling performance.

Minimized Downtime:

Opting for the best York YVAA microchannel replacement helps minimize downtime associated with cooling system malfunctions. Proactive maintenance and replacement strategies ensure that industrial processes continue seamlessly, avoiding costly disruptions.

Energy Efficiency Gains:

The best replacement microchannels may result in energy efficiency gains. This is particularly crucial for industries striving to reduce energy consumption and operating costs while adhering to sustainable practices.

Conclusion

Choosing the best York YVAA microchannel replacement is a strategic decision that can significantly impact the efficiency and longevity of industrial cooling systems. As industries navigate the complexities of evolving cooling requirements, selecting the right replacement microchannel becomes a critical step towards operational excellence. The best York YVAA microchannel replacement not only addresses performance issues but positions industrial facilities at the forefront of efficiency, reliability, and sustainability. In the competitive landscape of industrial equipment, the careful consideration of York YVAA microchannel replacement stands as a testament to the commitment to quality and innovation in industrial cooling solutions.