How Ultrasonic Testing Detects Early Turbine Damage

Maintenance engineers have the burden of keeping turbines online without compromising safety. Ultrasonic testing is a quick, non-destructive method to look inside critical components before small defects become forced outages. To know more about ultrasonic testing, click this link.

This article will discuss how the method works, what it finds, and why it contributes to long-term reliability and strategies.

Why Early Detection Matters

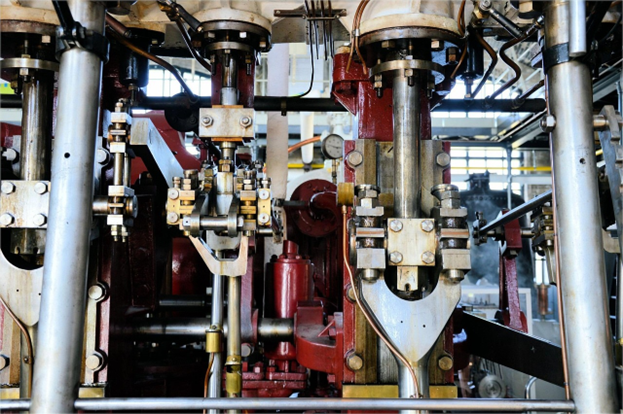

Turbine components operate under extreme heat, stress, and vibration. Even a small crack at a blade root or a flaw in a rotor forging can quickly propagate after these components begin to see loads cycling at speed. Finding defects early allows planners to bring them to a shop to repair during a planned outage, versus having to react to a trip event or catastrophic failure. Early data also aids spare-part strategies and reduces collateral damage to surrounding hardware.

What Is Ultrasonic Inspection?

Ultrasonic inspection sends high-frequency sound into a component and measures reflections from internal boundaries or defects. Technicians interpret the signals that come back on a screen, to locate and size discontinuities like cracks, lack of fusion, and other inclusions. The pressure wave travels through the metal so the component does not have to be cut or disassembled more than access allows – making this a core inspection method leveraged in non-destructive evaluation (NDE).

Assessors will consider geometry, material, and anticipated flaw types before settling on an inspection method. Many fleets leverage the speed and detail offered by phased ultrasonic testing and advanced methods for increased coverage. Commonly used methods include:

- Conventional pulse-echo UT for quick spot checks and general flaw indications.

- Phased array ultrasonic testing (PAUT) for steering and focusing beams providing 3D coverage of complicated geometries.

- Time-of-flight diffraction (TOFD) testing for indicating and sizing crack height utilizing diffracted signals at the tips of the cracks.

- Automated or encoded scanning to document position and create a repeatable, trendable map.

Common Turbine Problems Found With UT

Ultrasonic procedures are generally suited to high-stressed zones in steam and gas turbines. Inspectors routinely inspect blade roots and dovetails for fatigue cracking due to fretting, stress concentration, or vibratory response. Inspectors evaluate rotor bores, wheel rims, and compressor or turbine disks for inclusions and micro-fissures that can develop under cyclic loading.

Erosion-corrosion (https://www.corrosionpedia.com/definition/469/erosion-corrosion), and wall thinning of casings, valves, and extraction lines, are also common findings. These findings are particularly prevalent with older steam units. Ultrasonic thickness gauging identifies remaining wall thickness and identifies thinning patterns that indicate flow-induced wear. These results, in conjunction with other inspection methods, will be used to inform repair scope, consider viable re-rating options, and establish inspection intervals.

How Accurate Are Ultrasonic Methods?

The accuracy of ultrasonic testing is influenced by an assortment of factors: equipment configuration, transducer selection, calibration of the reference block, and part geometry. As long as surfaces can be accessed and there is good coupling, UT is capable of detecting small reflectors and also allows repeated size estimates that are acceptable for engineering decisions. With PAUT there is a higher detected probability when energy is focused at the appropriate acute angles. TOFD is a particularly good technique for estimating through-wall crack height.

Significance is still a judgement call based upon competency. Rough surfaces, complex shapes, and coarse-grained alloys can wrap noise and impact visibility of indications. This is the reason certified processes and verified sensitivity checks, along with coded scans, are utilized for critical components. The combination of having good records and trending gives the reliability to allow ultrasonic data to support run-repair-replace decisions.

Benefits for Long-Term Reliability

Ultrasonic testing increases a turbine’s asset strategy positively and extends it beyond a single outage. It provides another tool to utilize a risk-based inspection program in conjunction with condition-based maintenance focusing resources towards the most risk. Furthermore, should the engineer utilize a monitoring protocol, there is a way to compare current measurements to previous scans and safely determine enhanced monitoring growth rates or confirm repairs can take effect.

Planners routinely put the UT results attach to history of the operational history, chemistry reports, and vibrations history to establish a plan for action and behavior change moving forward. This context takes indications, then plan for action and beyond saving money and repeat failure.

Some of the significant long-term benefits of utilizing UT data include:

- Shorter and more predictable experiences from work scope defined up front

- More availability from less forced outages and more replacement all at-risk parts

- More budget-controlled replacements that are targeted and defined remaining life

- More margin of safety from addressing defects early and before the defect size is considered high

- A deeper digital record, leading to better future maintenance planning and inspections of future steam or gas turbine blade roots.

With the proper technique and procedures UT can provide the maintenance engineer with visibility inside the metal, when the engineer needs it.